Batteries for Electric Vehicles

The energy storage system, usually called the battery pack, is one of the most important parts of an electric vehicle. Batteries are used to store electricity generated during braking, acceleration, and charging. They provide power for propulsion, lighting, air conditioning, and many other functions. Lithium-ion batteries are the most common type of battery used in EVs today.

Types of Energy Storage Systems

All-Electric Vehicles

The battery pack in an electric vehicle is usually located under the floor of the car. This type of battery packs can hold about 75-85 kWh, some manufactures offer lower cost cars with reduce capacity and subsequent range. They provide enough power for short trips around town.

Plug-In Hybrid Electric Vehicle

A plug-in hybrid electric vehicle uses both gasoline and electricity to run the motor. A large lithium ion battery powers the electric motors while a smaller lead acid battery provides extra juice during acceleration. Plug-in hybrids use gas for longer trips and charge overnight.

Hybrid Electric Vehicle

This type of vehicle combines the best features of a conventional car and a pure electric vehicle. Its batteries are larger than those found in regular EVs because it needs to carry extra weight for the extra traction.

Different Types of EV Batteries

Lithium-Ion Batteries

Lithium-ion batteries are one of the most important technological innovations of our times. They enable us to use portable devices everywhere and anytime. But what makes them stand out from the rest? What sets them apart from other types of rechargeable batteries?

In short, they offer great advantages over traditional lead acid batteries such as high power density, low weight, excellent safety characteristics, very good cycle life and no memory effect.

The term “lithium-ion battery” refers to rechargeable cells composed primarily of one or more layers of positive and negative electrodes separated by a layer of electrolyte. These cells are commonly used in consumer electronics devices, including laptop computers, tablet PCs, smartphones, digital cameras, video game consoles, and electric cars.

There are several types of lithium-ion batteries, each designed for specific applications. For example, button-type batteries are typically small, lightweight, inexpensive, and able to deliver large amounts of power quickly. On the other hand, cylindrical cells are larger, heavier, less expensive, and capable of delivering smaller amounts of power over a longer period of time. In addition, there are prismatic and pouch-like designs that are specifically adapted to meet space constraints in certain mobile device configurations.

Benefits of Lithium-ion batteries:

*Cheaper to produce than nickel metal hydride (NiMH) and lithium polymer (LiPo) batteries.

*Longer lifespan – deliver 2-3,000 full recharge/discharge cycles compared with 1,000 for NiMH and LiPo batteries.

*Generate less heat during charging, so it can sustain a higher charge rate without damaging the battery.

*Can be charged to 100% without causing significant battery degradation, allowing owners to use the car closer to capacity for extended periods.

Nickel-Metal Hydride Batteries

A major challenge facing researchers today is developing battery technology that meets the needs of electric vehicles while maintaining safety standards. One promising solution is nickel metal hydride batteries. Nickel-metal hydrides are rechargeable batteries that use hydrogen gas to store electrical charge. They have a long life cycle, low weight, high capacity, and good performance under harsh conditions. However, the current manufacturing process requires expensive materials such as nickel hydroxide and cobalt oxide, leading to high costs. In addition, the production of hydrogen gas leads to excessive heating, making it difficult to maintain stable operating temperature. Finally, hydrogen leakage during charging and discharging causes safety issues.

To overcome these problems, a novel method for producing nickel-metal hydrides based on hydrothermal synthesis can be used. This approach uses inexpensive raw materials and produces a pure product without impurities. Demonstrations indicate that nickel-metal hydrids exhibit excellent electrochemical properties compared to those produced via traditional methods.

Benefits of Nickel-metal hydride batteries

NiMH batteries are less expensive to make and recycle than Li-Ion batteries. They’re also safer, since they don’t explode like Li-Ion batteries do. However, NiMH batteries aren’t quite as powerful as Li-Ion batteries, which makes them better suited for smaller vehicles such as scooters and motorcycles.

The main advantage of Li-Ion batteries is their ability to store energy efficiently. This allows manufacturers to use smaller cells and pack them into larger packs.

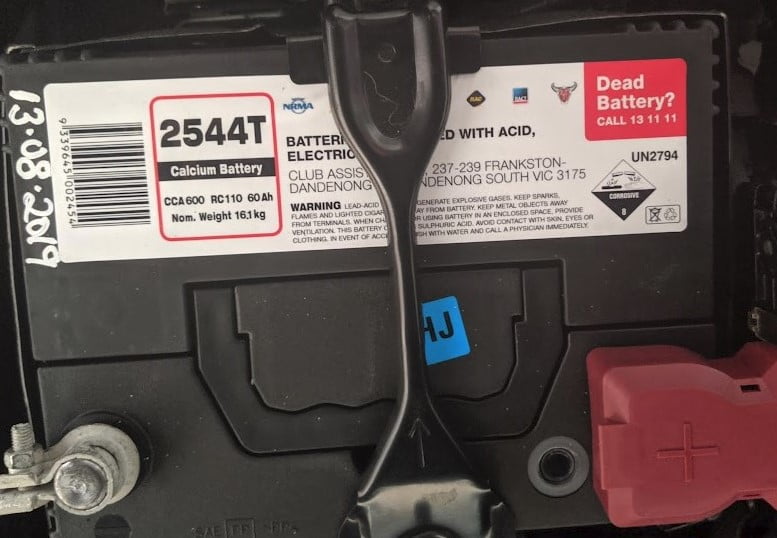

Lead-Acid Batteries

Lead-acid batteries are among the oldest types of rechargeable storage devices. They are cheap, simple, and easy to make. In addition, they are safe, reliable, and relatively maintenance free. Their main drawback is low specific energy, which limits their application in many applications.

High-power lead-acid cells are used in hybrid-electric cars to provide peak current demands during acceleration. These cells are expensive because they require rare metals such as lithium and cobalt.

Advanced high-power lead-acids are under development, but they are still too expensive for most applications.

Ultracapacitors

An ultracapacitor stores electrical charge in a polarized liquid between electrodes and an electrolyte. Capacitance depends on the amount of surface area in contact with the polarizable material and the dielectric constant of the solvent. A high dielectric constant allows the capacitor to hold more charge per unit volume.

The liquid’s surface area can increase by increasing the number of pores in the separator or decreasing the thickness of the separator. As the pore size decreases, the capacitance decreases due to the increased resistance to ion flow. Pores smaller than 10 nm are called nanocapacitors. Nanoporous carbon films have been used to make ultracapacitors.

A porous metal oxide film can be used instead of a solid polymer electrolyte. Metal oxides such as titanium dioxide or zirconium dioxide can be deposited onto a current collector to form a thin film. These materials are inexpensive and easy to synthesize.

ZEBRA Batteries

The ZEBRA battery is a high-performance battery that operates at temperatures up to 300 degrees Celsius. This makes it suitable for use in electric vehicles. These are very rare batteries because they require special materials such as lithium-metal phosphate, beta-alumina, and sodium chloride.

Zebra batteries were originally developed for electric vehicle applications, but they have been used in many fields including space exploration. They have been applied to satellites, spacecraft, and even submarines. Zebra Batteries are also being studied for use in renewable energy systems. This new technology might take some time before we see EV’s powered by this type of battery.